Projects Gallery

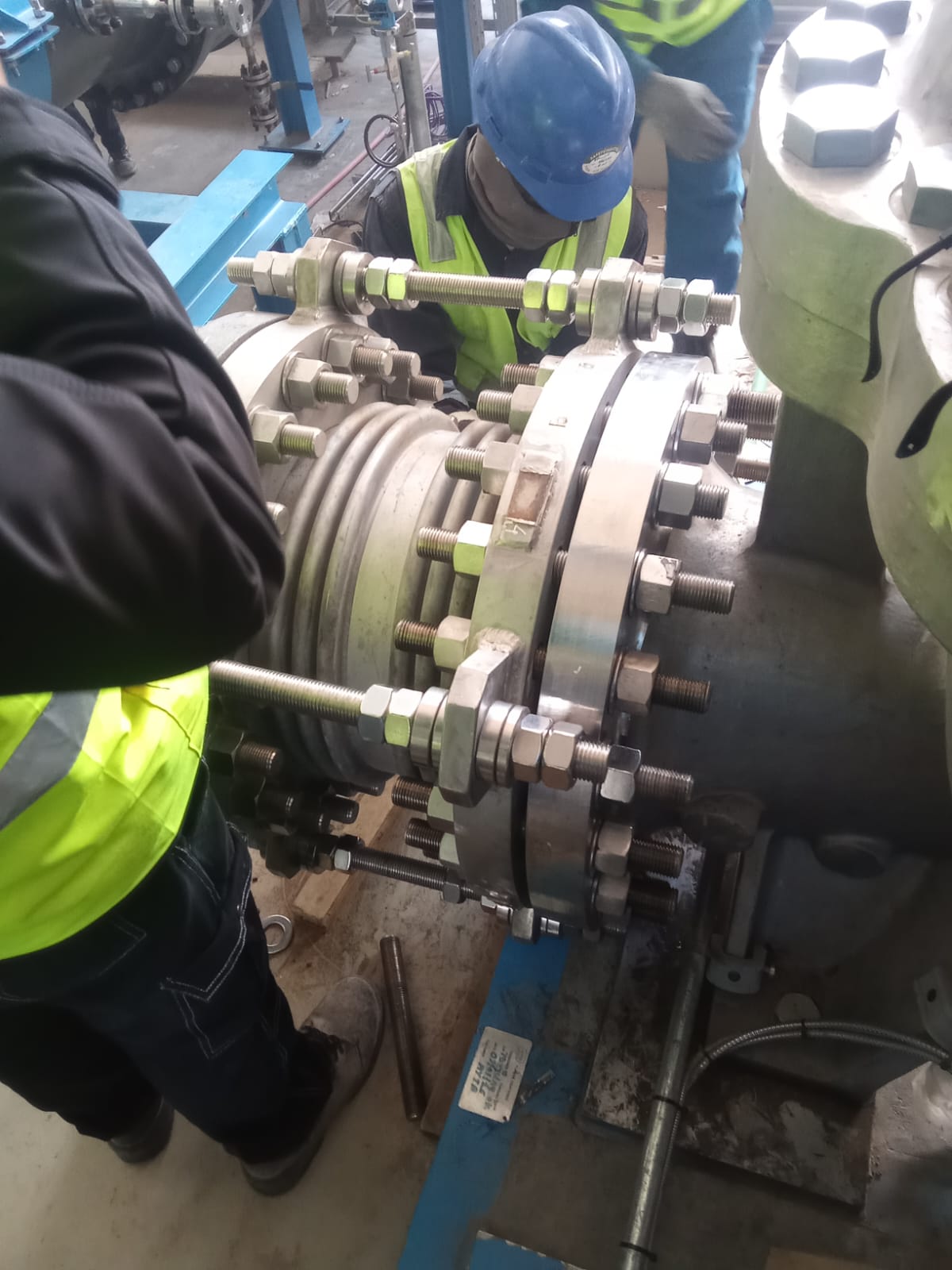

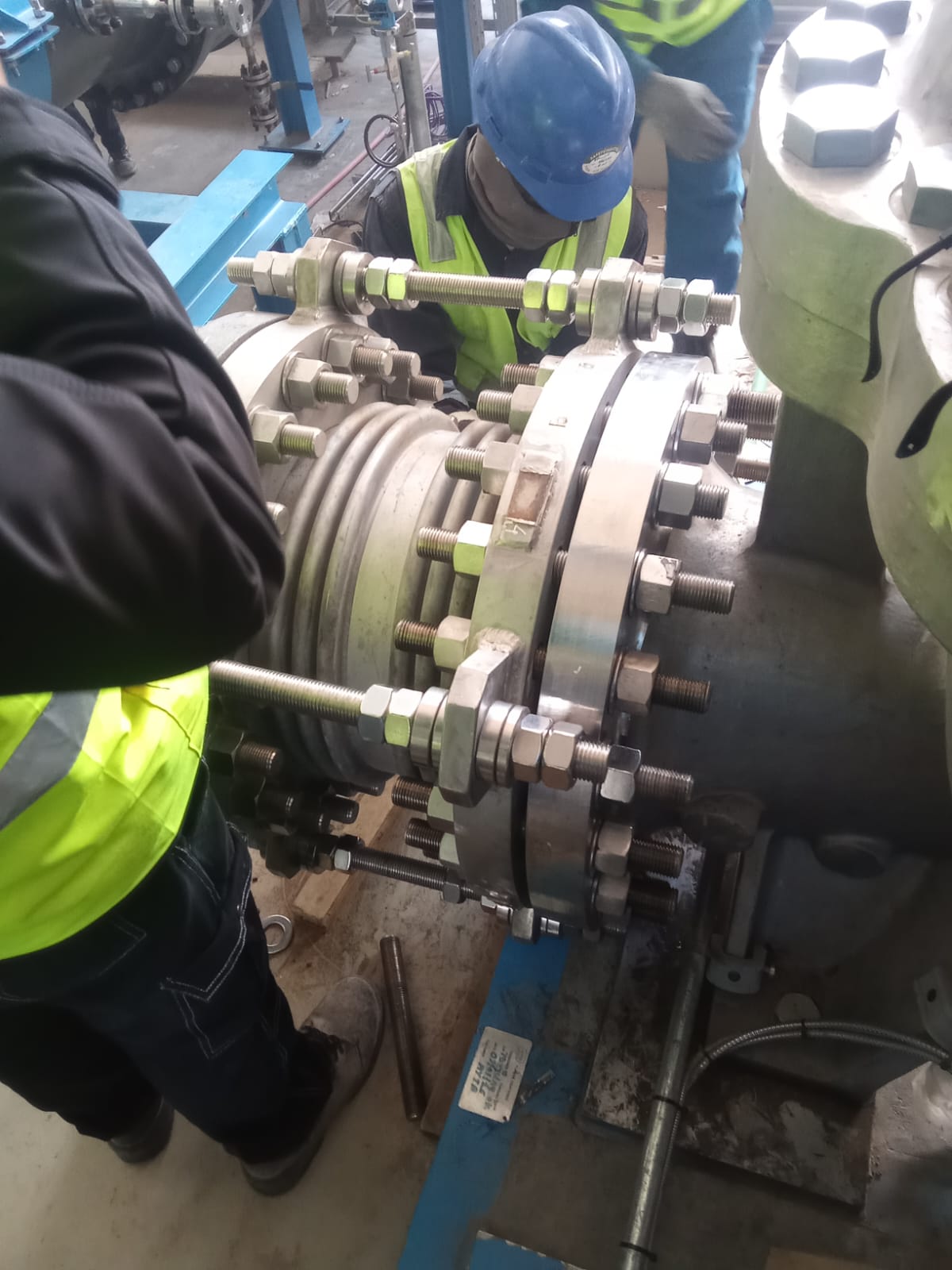

A glimpse of our on-site execution, fabrication, installation, and commissioning activities.

Since 2003, Universal Gate Contracting has delivered Mechanical, Electrical, and Hydraulic works— supporting industrial plants, pipelines, power projects, and complex site operations with disciplined execution.

A contracting company specialized in construction execution with strong management and wide experience in Mechanical, Hydraulic & Electrical construction. We focus on innovation, superior quality, customer service, and sustainable development.

From inception to completion, we prioritize quality, precision, and innovation. Our teams bring seasoned expertise across disciplines, with meticulous attention to detail and adherence to high industry standards.

Full-range project services encompassing project engineering, construction execution, fabrication, testing, and pre-commissioning support.

Mechanical & steel structural works, erection of warehouses, plant construction, structural repairs, demolition works, and specialized scaffolding.

Pipeline construction for Oil & Gas industry, jacketed/non-jacketed piping, process piping and complex site installation.

Heavy structures, tanks & vessels, multi-process welding (SMAW/MIG/TIG), blasting/painting/coating, and Aramco-standard portable cabins.

Meticulous preparation and rigorous application of procedures. Certified materials, documented checks, and testing for robust quality control.

We structure execution around clear scope, schedule control, resource alignment, and safe site operations— enabling confident handover and dependable results.

A snapshot of representative execution experience across power plants, desalination, and large facilities.

From complex pipework to heavy structural fabrication—our approach balances schedule control, safety, and verified quality.

A glimpse of our on-site execution, fabrication, installation, and commissioning activities.

We provide clarity and alignment on what constitutes success, plan thoroughly, monitor progress, ensure deliverable quality, and mitigate risks to keep projects on track.

We scale to match site conditions—maintaining skilled direct/indirect manpower and a growing fleet of equipment to handle critical situations and protect the project schedule.

Share your scope and timelines—we’ll respond with a clear plan and execution roadmap.